Sound or Acoustic Insulation

Noise reduction is a must, as noise has negative effects on physiological processes and human psychological health. The crowded and active nature of modern society is making noise control engineering increasingly important. Effective noise control can be achieved with a comprehensive understanding of sound phenomenon. For sound to be produced, three components are needed; a sound source, a medium and a detector. The sound source is a vibrating body that produces a mechanical movement or sound wave. The medium, such as air, transfers the mechanical wave. The detector, such as an ear, detects the sound wave. Accordingly, noise control can be achieved by three means. Primary methods include alterations at noise and vibration sources. Secondary methods include modifications along the sound propagation path, and tertiary methods deal with sound receivers. Primary methods are constrained by technical and economical parameters, while tertiary methods necessitate that each receiving person is treated individually. This makes the secondary methods that include vibration isolation, noise barriers, noise absorption and dissipative silencing relatively practical and cost-efficient.

The materials and structures using sound absorption and insulation materials to reduce ambient noise have received much attention. Noise-absorbing materials absorb unwanted sound by dissipating sound wave energy when it passes through and also by converting some of the energy into heat, making them every useful for the control of noise.

Most practical sound absorbing products used in the building and construction industry consist of glass-fiber or mineral-fiber materials. In the 1970s, public health concerns helped change the main constituents of sound-absorbing materials from asbestos-based materials to synthetic fibers. However, these non-biodegradable materials not only cause pollution of the environment, but also contribute significantly in increasing Co2 (Carbon dioxide) contributing to global warming.

Therefore, researchers have now directed their attention to finding sustainable and eco-friendly materials to be alternative sound absorbers.

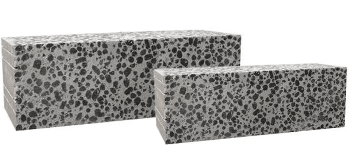

Expanded Clay Aggregate (ECA ®) or Lightweight Expanded Clay Aggregate is a round pellet structure produced by firing natural clay at temperature of 1200°C. The result is a hard, honeycombed structure of interconnecting voids within the aggregate. The particles formed are round in shape and generally range in size from 0-30 mm. Expanded Clay Aggregate (ECA ®) or Lightweight Expanded Clay Aggregate is very much bio-degradable, environment friendly, sustainable and cost effective solution for sound or acoustic insulation.

Benefits

100 % Inert

Light in Weight

Reduction of 40-50% Load

High Compressive Strength

Cylinder Compressive Strength 0.6 to 3.0 N/mm2

Micro Porous Structure

Aids Better Aeration

Non-Toxic & Eco- Friendly

Green Material, 100% Eco-Friendly and Sustainable

Surface Alkalinity

Neutral pH

Excellent Thermal Insulation

Thermal Conductivity 0.097 to 0.10 W/mK

Excellent Sound Insulation

Excellent Acoustic Insulation Property

Insect-Proof

Prevents Dengue and Malaria

Low-Coefficient of Thermal Expansion

Excellent Fire Resistance

1 to 6 hrs - 9 to 19 cm LAC 1100 kg/m³

Earthquake Resistant

Lightweight

Get a no obligation quote!